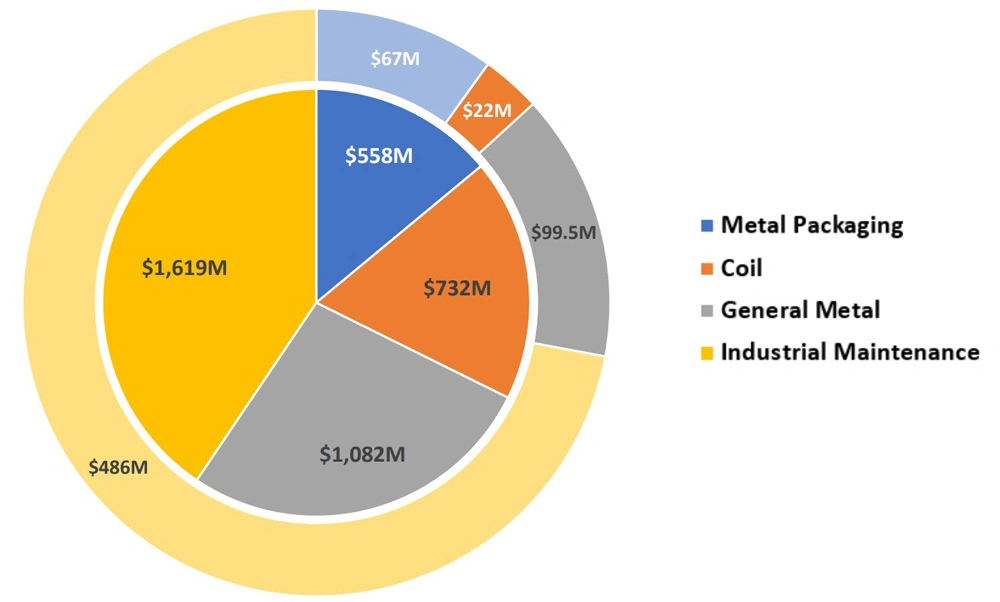

Total Coatings Market

Waterborne Coatings Market

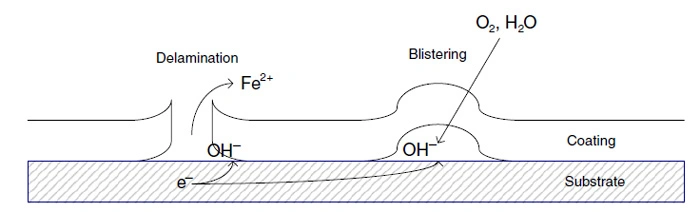

occurs when water molecules penetrate inside, disrupting the attractive force between the substrate and coating.

of coatings can be attributed to expansion due to swelling, gas inclusion, and osmotic processes.

occurs when the coating has:

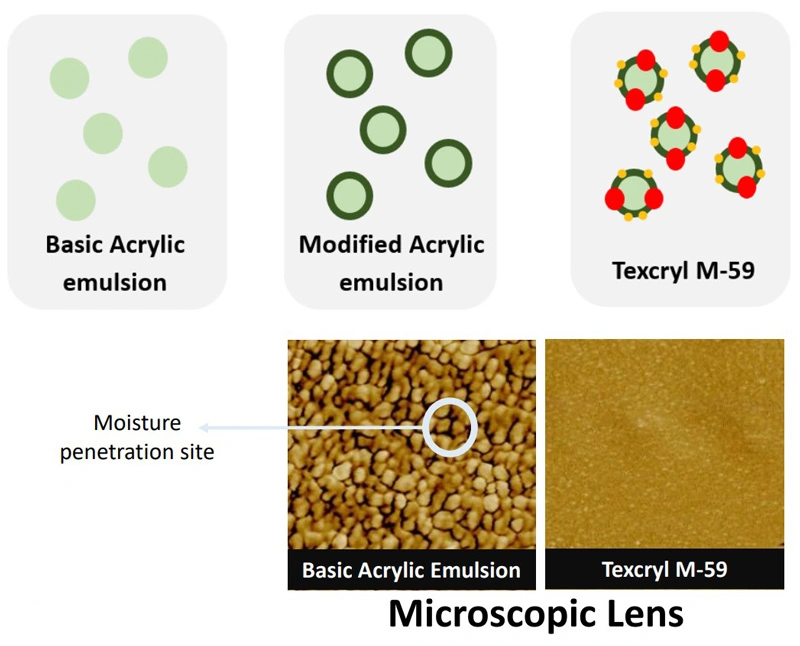

Good continuous film formation is critical. (without addition of cosolvents)

Good continuous film formation is critical. (without addition of surface modifying additives)

Emulsion when dried needs to be non conductive in nature.

Unlike traditional solvent based polyurethane coatings, PUDs provide a more environmentally friendly alternative with low volatile organic compound emissions and reduced health hazards.

exane HD-1346 is a film forming, aliphatic polyester based polyurethane dispersion, which provides an optimal balance between hardness and flexibility. It is used for formulating high performance metal coatings coatings with good gloss, protection, hardness and durability. Texane HD-1346 is compatible with crosslinking agents such as carbodiimides, aziridines, and isocyanates.

| Raw Material | Function | Manufacturer | Wt. % |

|---|---|---|---|

| Deionized Water | 17 | ||

| 2% HEC solution | Core building | 0.2 | |

| Ammonia | Neutralizer | 0.2 | |

| Biocide | 0.2 | ||

| UnoWet 9459 N | Wetting agent | Uno Chemie | 0.2 |

| Texcryl D50 | Dispersing Agent | Texochem Industries | 0.2 |

| Diethylene glycol | Cosolvent | 4 | |

| Red oxide Paste | Pigment | 20-25 | |

| Calcium carbonate | Filler | Texochem Industries | 14 |

| Zinc Phosphate | Corrosion inhibitor | 2 | |

| Texcryl M-59 | DTM Emulsion | Texochem Industries | 40 |

| Sodium Nitrite | Corrosion inhibitor | 0.5 | |

| Texcryl MT30 | HASE Thickener | Texochem Industries | 0.5-1 |

| Ammonia | Neutralizer | 0.2 | |

| Non silicone defoamer | 0.2 |

| Raw Material | Function | Manufacturer | Wt. % | Procedure |

|---|---|---|---|---|

| Deionized Water | 5 - 7 |

Prepare the mill base under high shear for 10-15min. Add the components in order. Set the mill base aside. |

||

| Texcryl D50 | Dispersing Agent | Texochem Industries | 0.5 – 0.8 | |

| Ammonia | Neutralizer | 0.2 – 0.4 | ||

| Non silicone defoamer | 0.1 – 0.2 | |||

| UnoWet 9459 N | Wetting agent | Uno Chemie | 0.2 – 0.5 | |

| Texcryl MT30 | Thickener | Texochem Industries | 0.3 – 0.6 | |

| Titanium dioxide | Pigment | 18 - 20 | ||

| Calcium carbonate | Filler | 7-10 | ||

| Texcryl M59 | DTM Emulsion | Texochem Industries | 57 - 70 |

Add the components in continuous stirring. |

| Deionized water | 5 - 7 | |||

| Non silicone defoamer | 0.1 – 0.2 | |||

| Ascotran H10 | Flash rust Inhibitor | Ascotec | 0.5 – 1.0 | |

| Asconium 142DA | Corrosion Inhibitor | Ascotec | 2 - 3 | |

| Texanol | Cosolvent | Eastman | 1.5 – 2.5 | |

| Mill base | ||||

| Biocide | 0.2 – 0.3 |