Tackifiers are low molecular weight component used in adhesive formulations, especially in tacky adhesives such as hot melt adhesives and pressure sensitive adhesives. As the name suggests, they are used to increase the tack in the adhesive. They can increase the tack as they increase the glass transition temperature and lower the modulus of the polymer system. Tackifiers also help in maintaining correct balance between the adhesive and cohesive strength of the system.

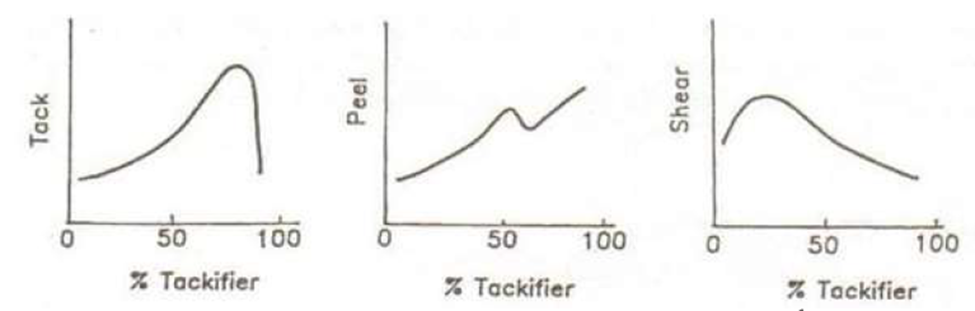

It is important to understand how the addition of tackifiers affects the other adhesive properties. From the graph below we see that adding tackifiers results in increase in tack but only up to a certain limit. Hence formulators must understand that there is a limit to increase in tack by addition of tackifier in the adhesive system.

.

Influence on Modulus

A pressure sensitive adhesive exhibits tack when the polymer is pliable to absorb energy rather than allowing it to propagate through cracks. The lower the modulus, easier it is for the PSA to deform, flow and make good contact to the bonding substrate.

Since tackifiers have low molecular weight (300 to 2000), they dilute the polymeric network and reduce the modulus.

A plasticizer by itself can also reduce the modulus of the polymer network, but it is ineffective in increasing the tack, as it decreases the Tg of the system.

.

.

Influence on Glass Transition Temperature

At temperatures near the glass transition region, the adhesive is very effective in dissipating energy and providing good adhesive bond. Tackifiers have Tg greater than room temperature, whereas the tacky adhesives have Tg lower than room temperature. Hence adding tackifier, increases the Tg of the system.

To be an effective pressure sensitive adhesive, the modulus of the system must be below 3.3 x 105 Pa and Tg must be close to the application temperature.

.

.

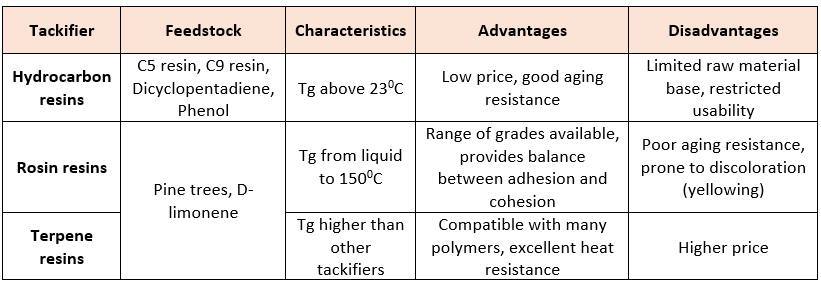

Types of Tackifiers

There are three main types of tackifiers:

- Hydrocarbon resins

- Rosin resins

- Terpene resins

.

.

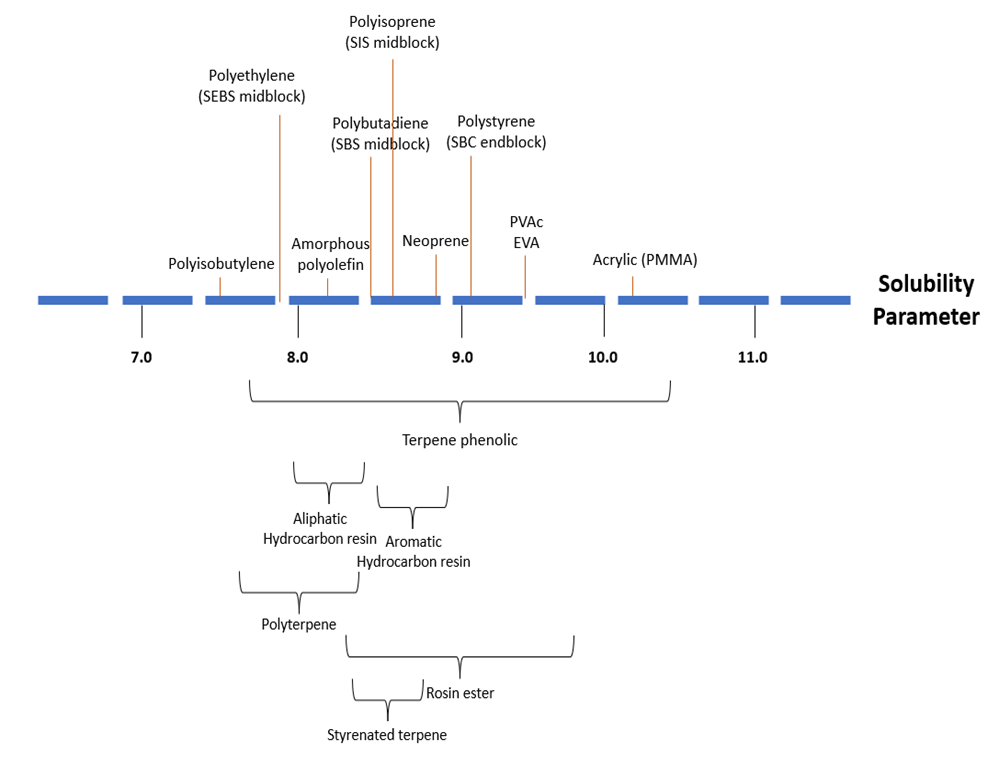

Compatibility

It is very important that the tackifier being used is compatible/soluble with the base polymer in adhesive formulation. Higher the compatibility, higher will be the tackification. If the tackifier is not compatible, then it acts as a filler in the system, i.e., it will increase the modulus and will not change the Tg.

Solubility parameter, molecular weight and molecular weight distribution determine compatibility.

For those who have access to DSC or other characterization equipment – You can check if the tackifier is compatible with the polymer by checking for the Tg value. If the tackifier is compatible, you will see only one Tg for the system, otherwise the system will show two different Tg.

.

.

.

Other criteria’s important when using tackifier

1. Softening Point: For the same tackifier family, a low softening point resin will be more compatible in a specific polymer than a higher softening point. Resins with higher softening points are less miscible in the polymer, but if compatible offer higher shear resistance and creep resistance.

2. Dosage: Modulus increase will begin in the range of 40%-60% of resin loading. However, tackifier content more than 20% generally results in lower cohesive strength. For natural rubber-based PSAs tackified with hydrocarbon resins, maximum tack is obtained at 50%-60% dosage of tackifier.

3. Compounding High viscosity tackifiers are pre-warmed for better handling. Tackifiers with higher melting point should be added early in the formulation stage to ensure complete melting and mixing. Soft resins can be added with fillers and other additives to make use of their wetting and dispersing properties, and relatively late addition can be useful for building tack.

.

Application of Tackifiers

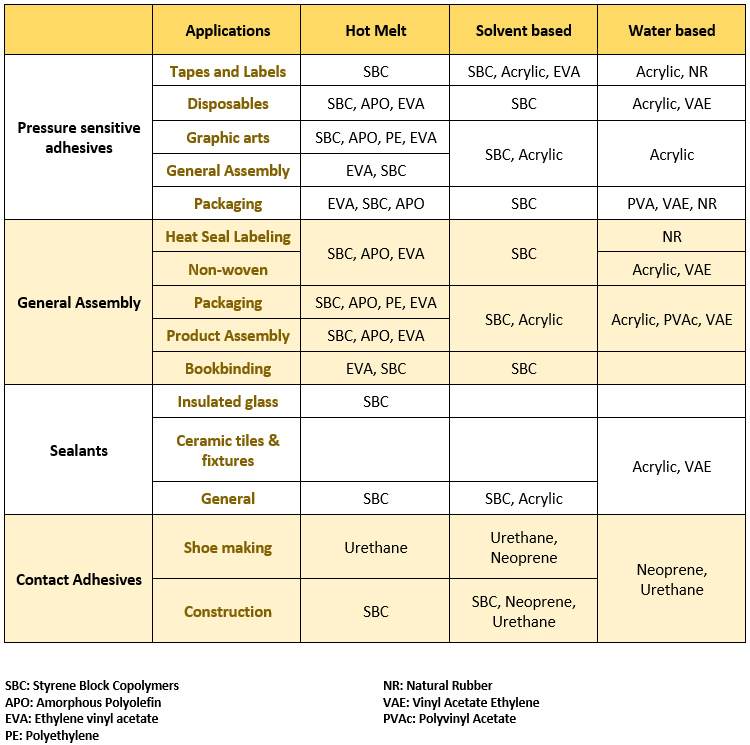

The primary application areas for different tackifiers are listed below in the table.

.

.

.

References

- Special Chem. Selecting tackifiers for Adhesives and Sealants.