The term “functional coatings” has been used as a buzz word in the industry just like “smart phones” in the tech industry. Functional coatings can be described as the coatings which have special properties and gives the surface new additional functions.

Though there are many types of functional coatings, in this Tech-File we will be discussing about those which are starting to gain some market attention.

.

Self Cleaning Coatings

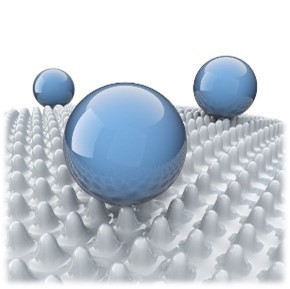

Self-cleaning coatings are those coatings which do not allow dust particles to settle on the surface. These types of coatings are based on one of the following two technologies:

- Superhydrophobic coating (where water contact angle > 1400)

- Superhydrophilic coating (where water contact angle = approx. 00)

Both categories clean themselves by the action of water. In a hydrophilic coating, the water is made to spread (sheeting of water) over the surfaces, which carries away the dirt and other impurities, whereas in the hydrophobic technique, the water droplets slide and roll over the surfaces thereby cleaning them.

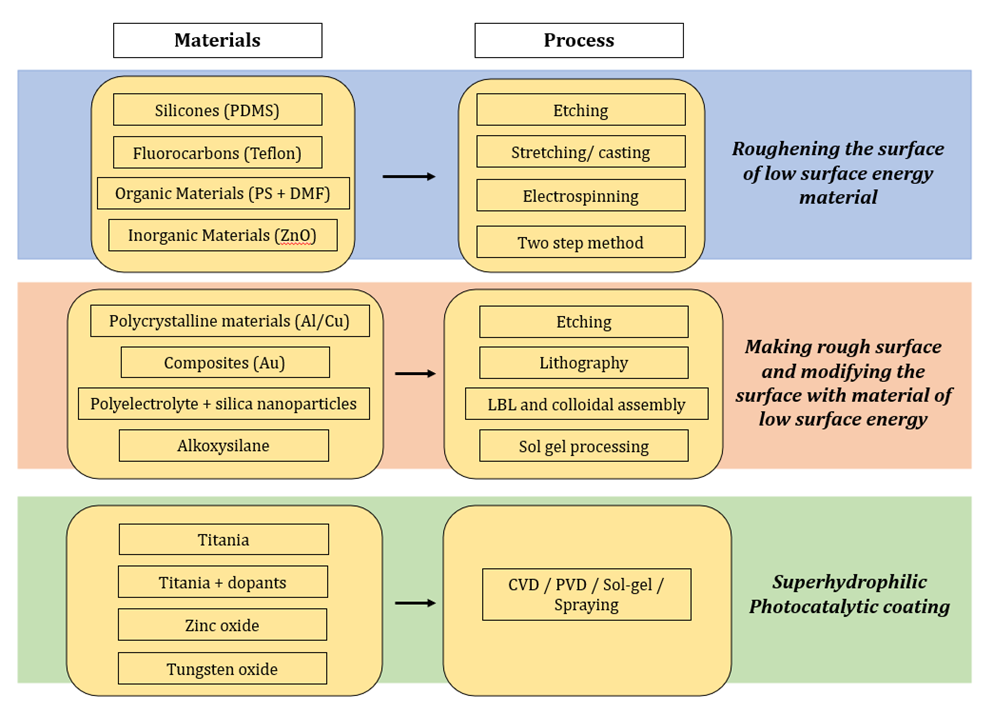

Superhydrophobic coatings are developed using coatings which have lower surface energy and/or which form a micro-rough structure. Low surface energy prevents water from spreading on the surface, and micro-rough surface prevents flattening of water drop.

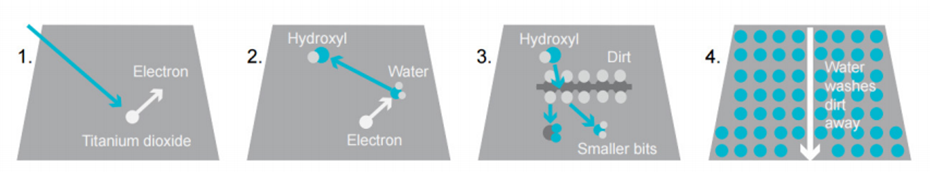

Superhydrophilic coatings work on the principle of photocatalysis. TiO2 has become a potential candidate exhibiting photocatalytic activity and it is widely used because of its non-toxicity, availability, cost effectiveness, chemical stability, favorable physical and chemical properties. In photocatalysis, Organic and oxidizable contaminants are degraded by the action of light on a suitable catalyst. This lowers the contact angle ~ 0°, thus making the surface superhydrophilic in nature. Such a surface has anti-fog properties because no discrete water droplets form on the surface, but rather a thin transparent water film.

.

.

Superhydrophobic and Superhydrophilic coatings also help in developing anti-icing, anti-fouling, drag reducing and anti-fog functional coatings.

.

.

Self Healing Coatings

Self-healing refers to the ability of materials to repair damage automatically without any additional external measures. Other terms for this behavior are “self-repairing”, “self-recovering”, and “autonomic repairing”.

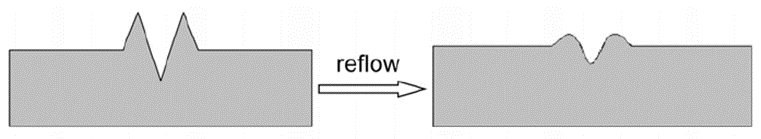

A lot of traditional coatings, for instance the classic chromate-containing anti-corrosion primers, can be self-healing materials because in these systems the chromate acts as a self-healing agent: In the event of damage, chromate crystals encounter the electrolyte, the chromate ions get solved and react with the metal substrate or with the oxide layer respectively, and so “heal” the damage in the coating. One might argue that high scratch resistance property in the coating might prevent coating damage and is better than using a self-healing coating. Though it might be an economically wiser decision to use coatings with high scratch resistance, they do not perform better than self-healing coatings in terms of aesthetic appearance. This is because the particles that lead to natural damage, for example sand grains or mineral dust, are normally harder than any clear coat which could be manufactured.

.

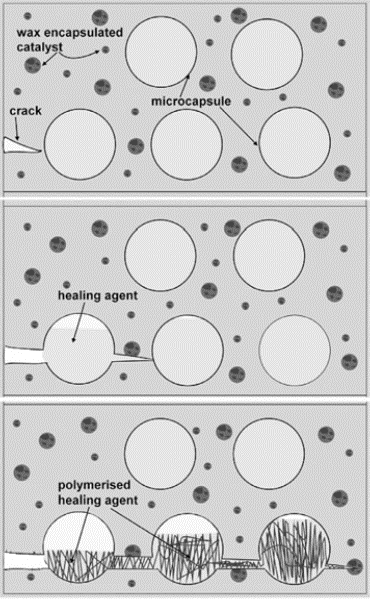

The most common method of developing self-healing coatings is by microencapsulation of crosslinkable healing agents.

Common healing agents used:

- Dicyclopentadiene

- Methyl methacrylate

- Linseed Oil

- Bisphenol A with latent curing agent

- Isophorone diisocyanate

- Epoxy resins

- Polydimethylsiloxane

The figure on the right gives a clear understanding about the healing mechanism in such coatings. Top: Microcapsules filled with polymerizable healing agent and catalyst embedded in a polymer matrix; Middle: Crack ruptures capsules, healing agent leaks out, and comes in contact with catalyst; Bottom: Healing agent polymerizes, seals the crack, and prevents crack propagation.

.

.

References

- European Coatings Tech Files. Vincentz Network. Functional Coatings. Volkmar Stenzel, Nadine Rehfeld. 2011.

- Ragesh, P., Ganesh, V.A., Nair, S.V. and Nair, A.S., 2014. A review on ‘self-cleaning and multifunctional materials’. Journal of Materials chemistry A, 2(36), pp.14773-14797.

- Biolin Scientific. Self Cleaning Coatings.

- Paint Pro – Lotusan Self Cleaning Paint.

- Biolin Scientific. Durability of superhydrophobic surfaces – the biggest obstacle towards real life applications. Susanna Lauren. 2016.