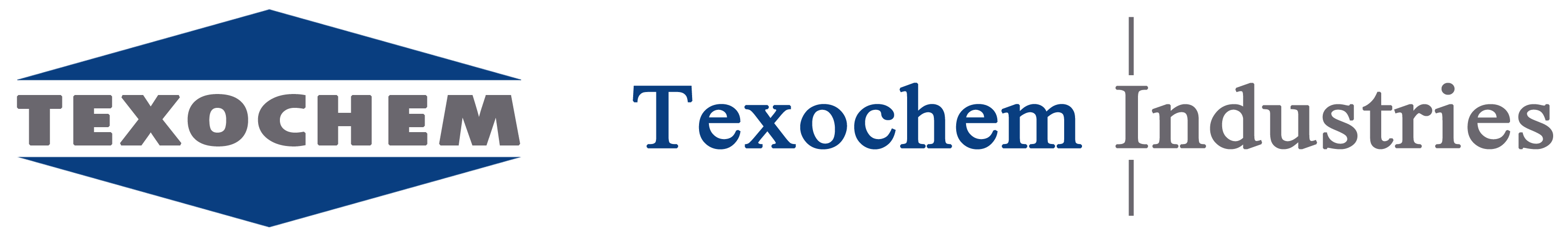

Pressure sensitive adhesives (PSAs) are permanently tacky products which adhere to substrates under the application of slight pressure (this may also be referred to as tack). These adhesives do not require solvent evaporation or chemical reaction for bonding and the bonding can be done at room temperature which makes the application of PSAs particularly easy, safe and consumer friendly. I can guarantee that we all have used some form of PSAs at some point in our life – be it for caressing our wound using bandages, or fixing broken items using tapes, or using labels for identifying our stuff. The market and technology of high-performance PSAs are expanding rapidly which is the result of an increased scope in the current and new areas of the applications. The statistics of world market share in the production of PSA tapes can be seen in the figure below.

.

Bonding Mechanism

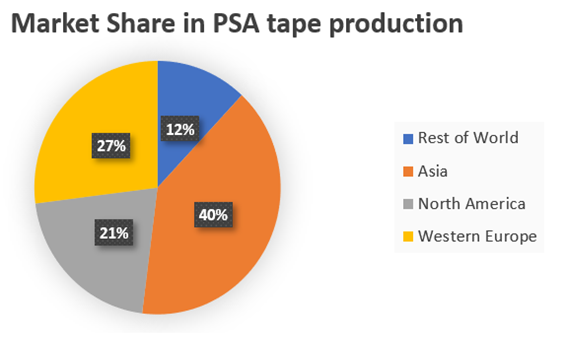

A PSA wets the substrate upon contact, without the help of organic solvents or water. This ability is like that of viscous liquids. After adhesive bonding, the pressure sensitive adhesive is able to transfer a certain amount of load. Typically, pressure sensitive adhesives exhibit a combination of the properties of liquids and solids, called viscoelasticity.

The plastic flow of a PSA during wetting and development of adhesion to the substrate is promoted by a low glass transition temperature (Tg) and low molecular weight. PSAs usually have Tg which are 40 to 70 °C below the application temperature.

.

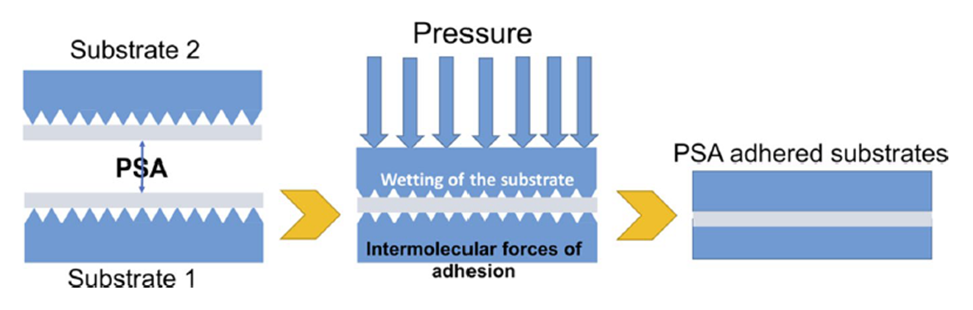

The ability of an adhesive to transfer loads between the bonded substrates, i.e., cohesion, is promoted by polymers of high molecular weight, high crosslink density and high glass transition temperature. Both properties are to some extent contradictory, which is why pressure sensitive adhesives are always compromises. A combination of high molecular polymers of low glass transition temperatures and low molecular resins mostly makes for an acceptable compromise. The application determines the levels of adhesion and cohesion needed by pressure sensitive adhesives.

.

.

Applications

Since PSAs comprise of a broad range of polymers and chemistries, it encompasses a wide variety of application segments. The easiest way to classify the different application area is by differentiating the PSAs based on their load bearing capacity (or commonly called as peel value). Peel value is the peeling force needed to effect separation between the bonded substrates at a specific angle (90° or 180°).

It is necessary to optimize the adhesive and cohesive strength of the adhesive to meet the desired application requirement.

| Pressure Sensitive Adhesive | Peel value at 180° (N/25mm) |

| Extremely durable | > 14 |

| Durable | 10.0 – 14.0 |

| Partly Removable | 6.0 – 10.0 |

| Removable | 2.0 – 6.0 |

| Easily Removable | < 2 |

.

Types of Pressure Sensitive Adhesives

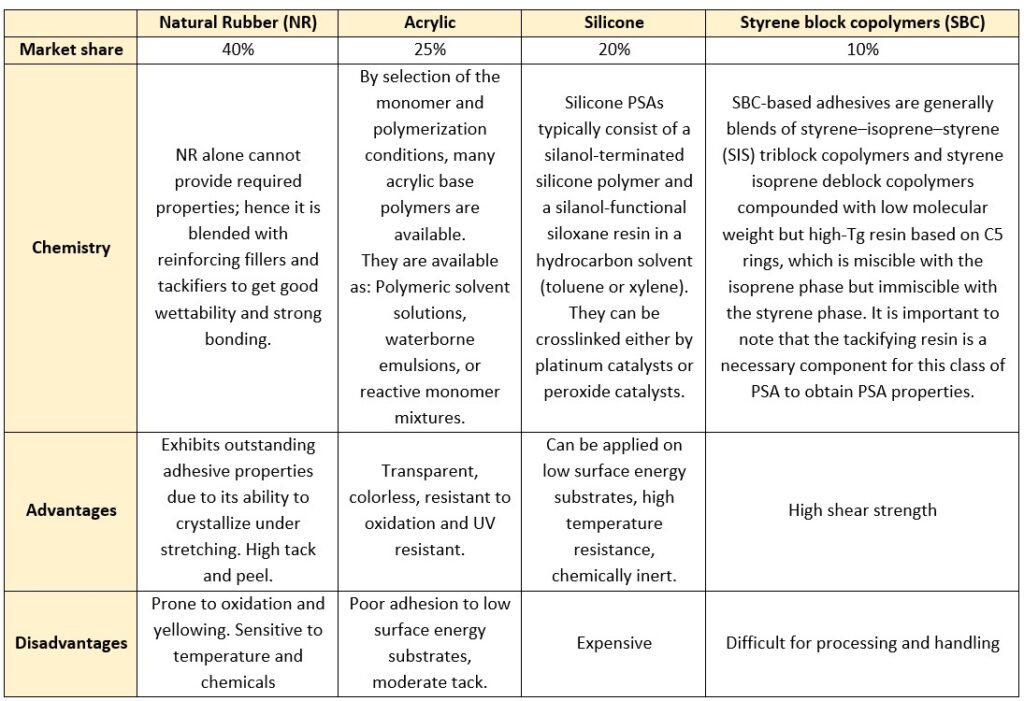

Various chemistries have been explored to develop PSAs for different applications. Natural Rubber was the first chemistry used to develop PSAs, and still dominates the list. Within natural rubber-based PSAs, solvent based systems have been the most used system. But the global drive for shifting away from solvent-based systems, led to growth in acrylic based PSAs. Though solvent-based acrylics are also available, research in water-based acrylics has promoted quick developments for high performance aqueous systems. The third-most used PSA belongs to the silicone chemistry. They are typically used for those applications where both rubber and acrylic based PSAs fail to perform as per expectations. Silicones have high temperature stability and can be applied on difficult to wet substrates such as polyimide, poly tetrafluoroethylene, polyester, and inorganic glass fiber cloth.

Table below summarizes the types of PSAs and their key characteristics.

.

Polyurethane and Epoxy based PSAs are also available in the market, but not as much as the types mentioned in the table above. We can say they are still in the development stage and are trying to enter the market gradually. Polyurethane PSAs are synthesized by reacting polyol with an isocyanate, which results in hard and soft segments within the same polymeric chain. This combination of hard and soft segments in the same chain enables the formulators to achieve viscoelastic properties and variety of other properties for specific applications.

Epoxy based adhesives are already well known in the field of structural adhesives, but their development for PSAs is being promoted to provide a cost-effective alternative to silicone PSAs.

.

References

- European Coating Tech Files. Vincentz Network. Formulating Adhesives and Sealants. Bodo Muller, Walter Rath. 2010.

- Polymer Bulletin. Springer. Developments in Pressure sensitive adhesive: A review. Sachin Mapari, Siddhesh Mestry, ST Mhaske. 2020.

- Only Trainings. Pressure Sensitive Adhesives (PSA): Know How for Beginners As Well As Professional Formulators

- Adhesives and Sealants Industry. Pressure Sensitive Adhesive 101. Kurt Schramer. 2009.