The use of coatings for fresh fruits and vegetables is not a new concept. Fruits and vegetables are coated in nature by a natural waxy coating called cuticle, consisting of a layer of fatty acid related substances such as waxes and resins, with low permeability to water.

Wax was the first coating used in fruits, especially in citrus fruits. It is believed that they were applied to oranges and lemons at the beginning of the 12th or 13th centuries in China. Later, hot melt paraffin waxes, carnauba wax and colloidal emulsions based on oils/waxes dispersed in water, started finding commercial acceptance.

These coatings are used to control the moisture transport and permeability of Oxygen and Carbon dioxide, and to reduce surface abrasion during fruit handling.

.

Need for Edible Coatings

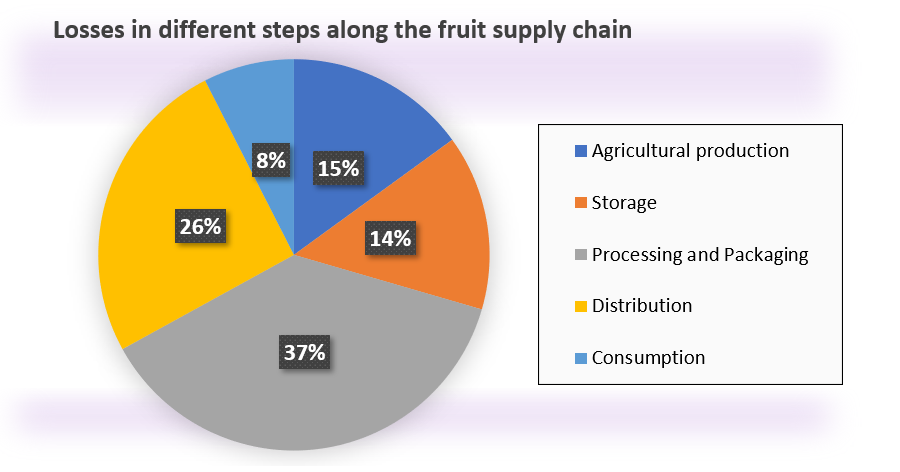

Postharvest losses of fruits and vegetables occur at all points in the value chain from production in the field to the food being placed on a plate for consumption. Postharvest activities include handling, storage, processing, packaging, distribution, and marketing.

Fruits and vegetables have a short shelf life varying from few days to few weeks. They continue to lose water after harvest, causing shrinkage and loss of weight. They are also easily damaged by insects or microorganisms during post harvesting conditions. From data collected globally, it is seen that about 14.5% of losses occur during the storage phase. As a consequence of growth in the global consumption market, efforts need to be taken to reduce wastage in the supply chain process.

.

.

Harvested fruits and vegetables are considered to be living organisms because their metabolic functions continue during the postharvest storage.

.

In general, the higher the product’s respiration rate, the shorter is its storage life.

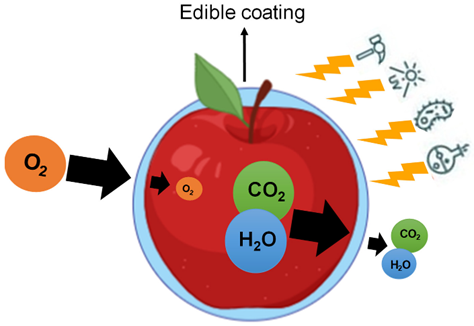

Thus, one possibility to extend the shelf life of these products is to minimize their respiration rate, by, for example, adding a barrier around the product to modify the composition of storage gaseous atmosphere to which postharvest products are exposed.

.

Cold storage techniques apply this exact concept of reducing the respiration rate – by diminishing the oxygen content in the atmosphere. However, oxygen levels must be maintained – very low oxygen content can increase anerobic respiration, defeating the purpose of increasing the shelf life.

Edible coatings can also be applied to obtain similar effects to the cold storage technique. These coatings can delay the ripening of fruits by modifying their internal atmospheres (decreasing oxygen and/or increasing carbon dioxide, as well as inhibiting ethylene biosynthesis and action) acting on skin permeance to gases. This effect is mainly achieved by blocking the pores on the fruit surface.

.

.

Define Edible Coatings

Edible coatings may be defined as a thin layer of material that covers the surface of the food and can be eaten as part of the whole product. The composition of edible coatings must thereof conform to the regulations that apply to the food product concerned.

Edible coatings must follow some functional requirements, which also depend on the kind of coated product and its metabolic pathways, such as:

- Sensory properties: Coating must be transparent, tasteless, and odorless

- Barrier properties: Coating must have an adequate water vapor and solute permeability and selective permeability to gasses and volatile compounds.

.

Composition of Edible Coatings

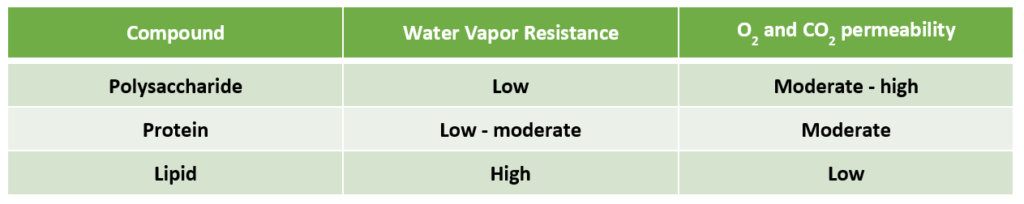

A range of polymers can be used in edible coatings formulation. However, their mechanical and barrier properties are intrinsically linked to the physical and chemical characteristics of their constituents. The polymers most used in the preparation (alone or in combinations) of edible films and coatings are:

- Polysaccharides (starch, pectin, cellulose, alginate, and carrageenan)

- Proteins (gelatin, casein, wheat gluten and zein)

- Lipids (stearic acid, waxes, and fatty acid esters)

.

Polysaccharides, being hydrophilic in nature, show poor water vapor resistance, but find a great range of application in edible coating formulations because of its effective gas barrier properties.

Casein and Whey protein based edible coatings are attractive for food applications due to their high nutritional quality, excellent sensory properties, and good potential to adequately protect food products from surrounding environments.

Lipid based coatings have low affinity for water, which explains their low water vapor permeability. As the carbon number increases (from 14 to 18), moisture barrier efficiency of the fatty alcohols and fatty acids increases – and does not favor water solubility in the film.

.

Composite Edible Coatings

These are those edible coating systems which are created by subsequent deposition of different layers of coating. Bilayer coatings are formed in two stages: in the first stage, the layer of polysaccharide/ protein is cast and dried; in the second stage, the lipid layer is applied.

Monolayer composite lipid coatings are also possible, wherein the lipid is dispersed in the hydrophilic phase of an emulsion. For e.g., emulsified coatings can be obtained by mixing mesquite gum and a combination of some lipids (candelilla wax, mineral oil, oleic acid, or beeswax).

Although emulsified coatings are less efficient than bilayers due to the non-homogenous distribution of lipids, they have received more attention as they require only one drying step instead of two. Moreover, both their hydrophilic and lipophilic properties allow their adhesion onto any support whatever its polarity and exhibit good mechanical resistance.

.

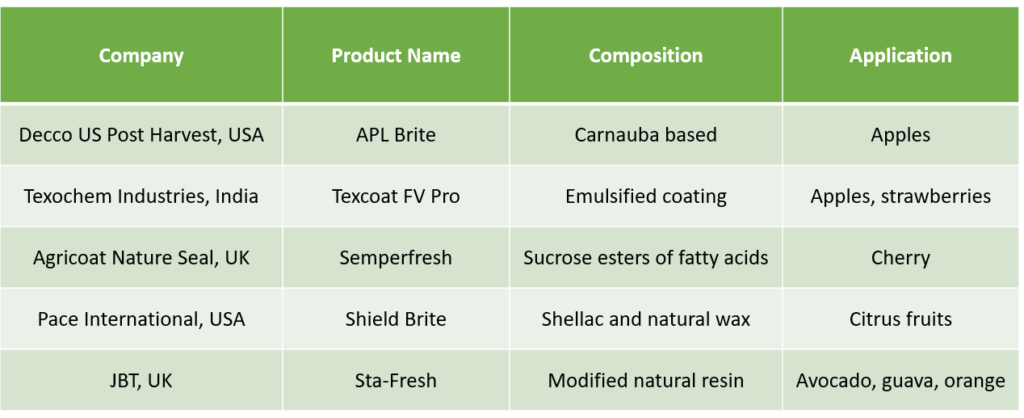

Commercial Edible Coating Technologies

.

Future of Edible Coating Technology

We expect the trend to focus on the development of effective delivery coatings with bioactive compounds to extend shelf life and improve the quality of the food. These coatings would act by releasing novel bioactive components like vitamins, nutraceuticals, enzymes, probiotics etc. into the food matrix throughout time.

Recent studies point to the application of micro and nano technologies to develop coatings which incorporate encapsulated compounds that are released by a certain stimulus such as pH, temperature, or osmotic changes in the medium.

.

References

- Fresh Produce. Development of Edible Coatings for Fresh Fruits and Vegetables: Possibilities and Limitations. Maria Vargas et al. 2008.

- Postharvest management of fruits and vegetables. Nano emulsions as Edible Coatings: A Potential Strategy for Fresh Fruits and Vegetables Preservation. Josemar Goncalves de Oliveira Filho et al. August 2021.

- Vacker. Cold Room for Vegetable, Fruits.

- Food Hydrocolloids. Evaluation of edible films and coatings formulated with cassava starch, glycerol, carnauba wax and stearic acid. Marcela Chiumarelli et al. November 2013.