When working with white pigments, it is very important to have a basic understanding about light scattering and its different effects. Since titanium dioxide (TiO2) is the most used white pigment, we would study about light scattering using TiO2 as our reference. In this article, we will share some key points which help you understand your pigment better.

Unlike colored pigments that provide opacity by absorbing visible light, TiO2 and other white pigments provide opacity by scattering light. This scattering is possible because the white pigment can bend light.

.

It is easier to get opacity with black pigment than with white pigment. Black opacity is achieved through one light-particle interaction and light absorption . Whereas white opacity requires multiple light-particle interactions and scattering.

.

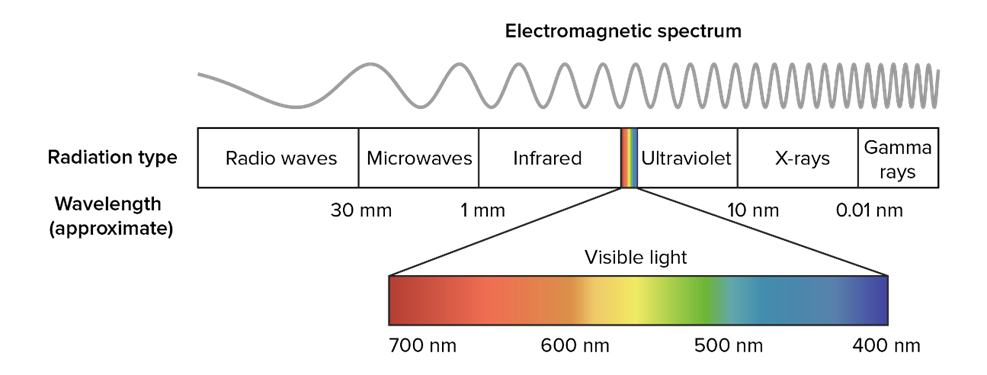

Just like pigment particles are characterized by their particle size, light rays are characterized by their wavelengths. The wavelengths we are concerned primarily is of the visible spectrum, which falls within the range of 400 – 700 nm.

.

.

.

Refraction, Diffraction and Opacity

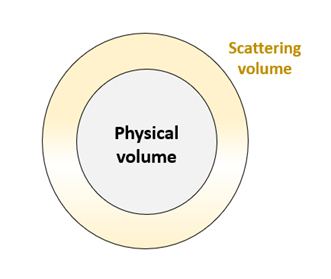

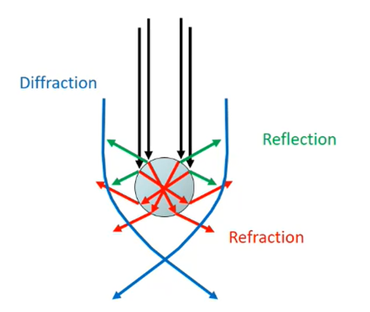

Every pigment particle has a scattering volume around its actual physical volume. Light rays entering the scattering volume are scattered by either reflection, refraction, or diffraction. If there is enough pigment in a system, all light striking the surface will be scattered outward (except for little absorption by the polymer or pigment) and the system will appear opaque and white.

.

Figure: Image indicating scattering volume of a pigment particle (left); Different paths of light passing through the scattering volume of the particle (right)

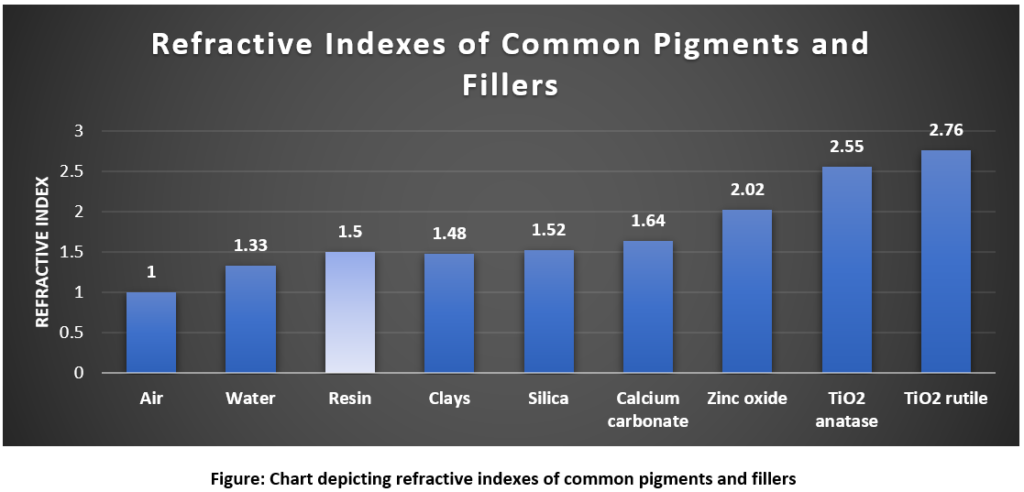

Refraction occurs when the light enters the pigment particle and gets bent based on the refractive index of the material. Refractive index is that property which helps in determining the opacity of a pigment. For example, refer to the chart below for refractive indices of various pigments and fillers.

.

.

We see that the rutile grade of titanium dioxide has the highest refractive index, meaning it has the highest strength of bending light. Fillers (clay, silica, and calcium carbonate) have low refractive indexes, like polymeric resins, hence they can’t scatter light as good as TiO2.

.

The hiding power of a white coating is determined by the magnitude of the difference between the refractive indices of binder and pigment or filler; the greater this difference, the greater is the hiding power. Large differences always result with air, which is why colorless fillers (extenders) appear white in powder form.

.

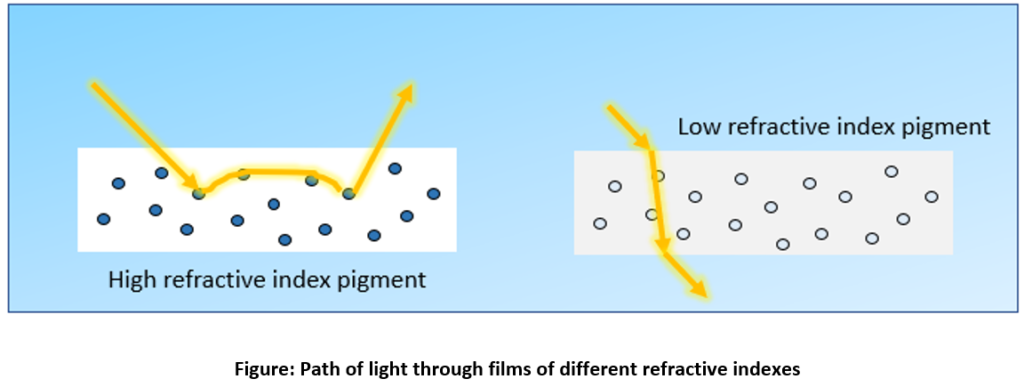

When the particle can bend the light effectively, it sends back the incoming light from the surface, making the surface appear white. When the refractive index is low, light passes easily through the thin film, making the surface appear grayish or less opaque.

.

When the distance between the particle and light ray is less than the wavelength of the light, diffraction occurs. Diffraction is a very important phenomenon in case of TiO2 particles, because of their low particle sizes. Smaller TiO2 particles will scatter the lower wavelength, while larger particles will scatter the higher wavelength region. So, a mix of particle sizes helps in complete scattering of light.

.

Effect of Pigment Volume Concentration

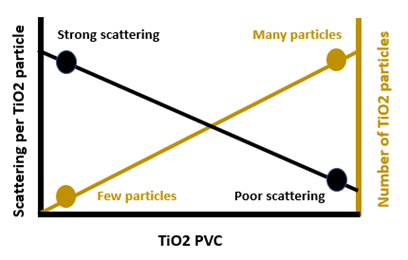

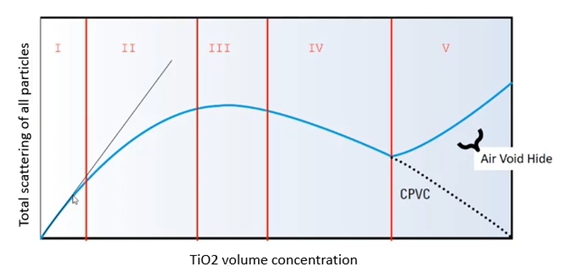

It is important to note that when number of pigment particles is high (Pigment volume concentration is high), there is a lot of overlapping in scattering volume, which decreases the effective scattering volume. Another graph below shows the different regions categorized based on pigment concentration and its respective scattering. For best performance, all formulations should be based in region 2 and region 3. We can observe that scattering is higher in region 5, but that is due to the air voids which form after exceeding critical pigment volume concentration (CPVC), forming a porous surface.

.

Figure: Graphs indicating effect of pigment volume concentration on TiO2 scattering

.

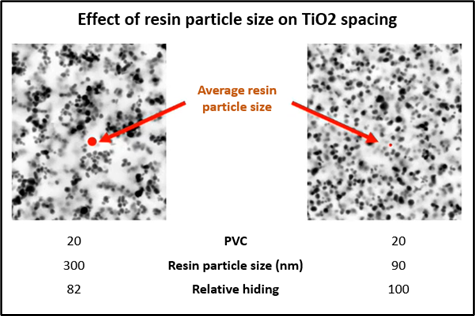

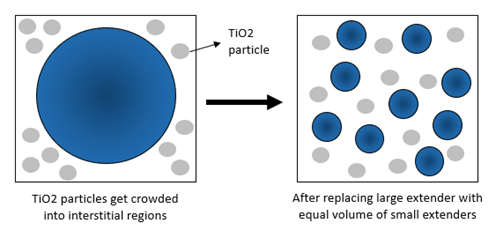

Effect of resin and extender size on TiO2 scattering

Smaller resin size allows easy dispersion of TiO2, while larger resin particles push the pigment particles to agglomerate. Similarly, the particle size of the extender used in the paint formulation also impacts the TiO2 scattering. Larger extender particles tend to push the TiO2 particles to agglomerate, whereas smaller extender particles reduce TiO2 crowding. Hence the formulators can expect to see better opacity in systems with extenders having low particle sizes.

.

.

References

- Khan Academy. Light and Photosynthetic pigments

- Chemours – Polymers, Light and Science of TiO2

- American Coatings Show 2020. TiO2, Light scattering and White; Michael Diebold.

- Theoretical study of the scattering efficiency of rutile titanium dioxide pigments as a function of their spatial dispersion. Jean-Claude Auger. Journal of Coatings Technology and Research. 2009.