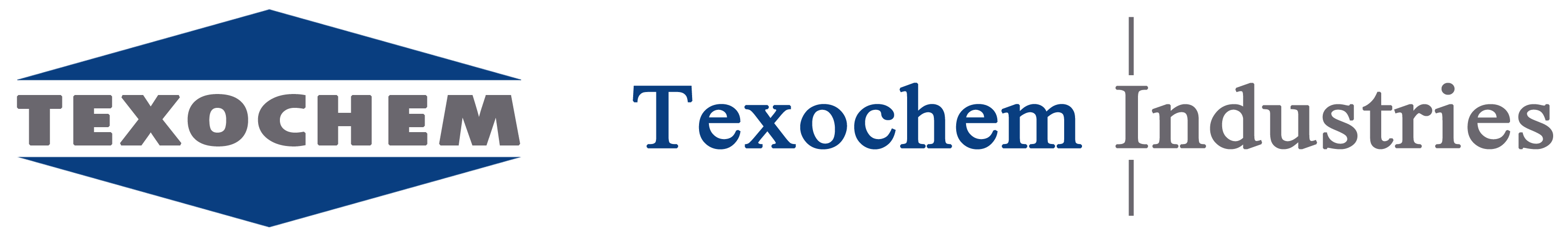

In solvent borne paints, flow properties can be regulated by the molecular weight of the dissolved binder. However, in waterborne formulations, rheology must be adjusted via additives (thickeners) as the binder is present as dispersed polymer particles.

There are many different chemistries that can adjust the rheology of a paint and correct thickener choice will depend on a number of factors, not only limited to the type of thickening desired, but also how and when the thickener is to be incorporated and which other additives are present in the system.

.

Correct thickener choice will affect color acceptance and stability after color addition. Other factors to consider include the correct selection of dispersing agents (and correct dosage!) as this leads to an increase in solids content whilst maintaining low viscosities.

.

Thickeners can be broadly separated into inorganic and organic thickeners for waterborne and solvent borne formulations. The below list is not exhaustive but provides an overview of various thickener types available:

.

Inorganic Thickeners

.

Organoclays

Organoclays or smectites encompass a variety of naturally occurring materials and consist mostly of sodium or calcium montmorillonites and hectorite. Smectites such as bentonite are highly swellable expanding lattices which, through modification with organic alkyl groups, can be used to provide shear-thinning to aqueous and solvent borne coatings.

Clays are natural materials and can be a cost-effective method of controlling rheology. However, they have limitations, especially with regards to clear coats or applications with high-optical requirements.

.

Fumed Silica and Silica Dispersions

Pyrogenic fumed silica is widely used as an anti-settlement and rheological additive in coatings. It is produced via flame hydrolysis of silicon tetrachloride (SiCl4) and can be either untreated (hydrophilic) or surface treated with various organic groups to produce hydrophobic silica.

Aerosil Fumed Silica was the first to be produced commercially and is used in coating formulations for imparting thixotropy, anti-sag, and anti-settling. When properly dispersed, the silica particles form a hydrogen-bonded network which is easily broken down under shear.

In addition to improved thixotropy, selecting the correct grade of AEROSIL® also imparts benefits to the dry film including improved scratch resistance and improved water resistance and corrosion protection.

Despite low addition levels, typically 0.3 to 1.0% AEROSIL® (on total formulation), dispersion requires high shear and therefore now silica dispersions are being made available for easier handling and incorporation.

.

.

Organic Non Associative Thickeners

Non-associative thickening occurs due to the entanglement of water-soluble, high molecular weight polymer chains. Formulations thickened this way display good stability and anti-settling properties as they become highly elastic. The downside however is that they often have limited flowability and the elastic properties can result in increased spattering.

Cellulose Ethers

Cellulose ethers are naturally sourced materials produced via reaction of cellulose with an alkali before substitution with methyl (MC), ethyl (MEC), hydroxyethyl (HEC), or hydrophobic end groups. This etherification process makes cellulose water-soluble and through adjusting the chain length of the cellulose backbone, a wide range of viscosity profiles can be achieved.

Cellulose ethers are often used to provide medium to high viscosities and in low to high PVC acrylic paints. As they improve water retention, they can help increase open time and offer good compatibility with other additives in the system. However, drawbacks include poorer levelling, higher spattering, and poorer water resistance, and they are more prone to biological attack.

.

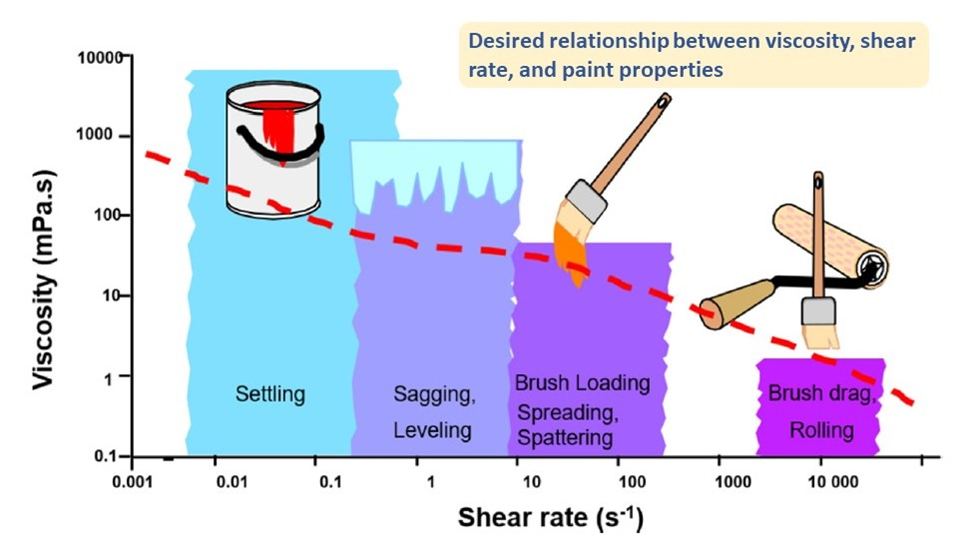

As seen in (a), associative rheology modifier are surfactants with a hydrophobic group at each end. When a hydrophobic group encounters another hydrophobic group or particle, a new association occurs. When a sufficient amount of associative rheology modifier exists, a micelle is formed at each point as seen in (b) creating an overall net-like structure.

.

Alkali Swellable Emulsions

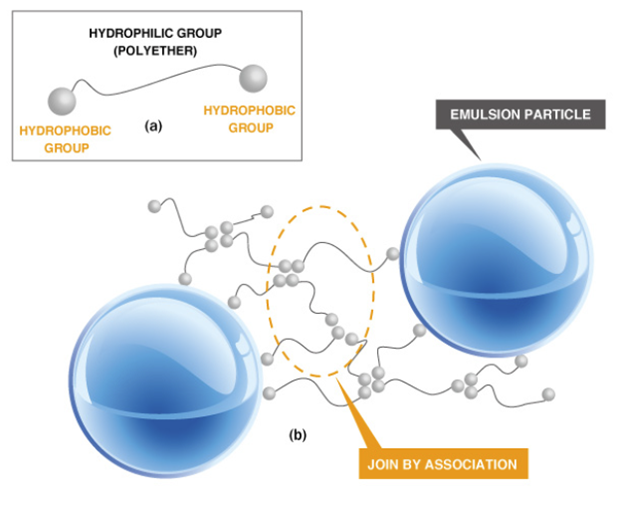

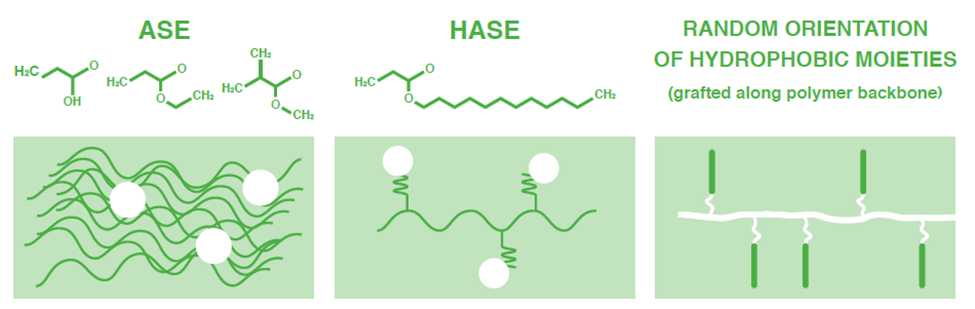

Alkali swellable polymers (ASE) are dispersions of acid-functional acrylic polymers and are particularly efficient at increasing low shear viscosity. Under acidic conditions, the acrylic polymer is tightly coiled however on increasing the pH of the system above pH 7, these long acrylic chains become soluble in water thus thickening the solution through entanglement.

.

.

ASE thickeners impart elasticity into the system and are therefore a good choice for in-stability, however can result in increased spattering as a result. Care is also needed when incorporating if using a volatile alkali such as ammonia as evaporation can result in localized pH decreases and instability.

.

Organic Associative Thickeners

Associative thickeners bridge the gaps between binder molecules, pigments, and fillers by creating an associative network. Hydrophobic parts on the thickener molecule associate with binder particles by adsorption at the surface or by ion-dipole interaction. The created bonds generate a given resistance against higher shear stress though can be broken down under shear. Often associative thickeners give rise to thixotropy as once shear is removed, there is a delay before the associative network rebuilds.

.

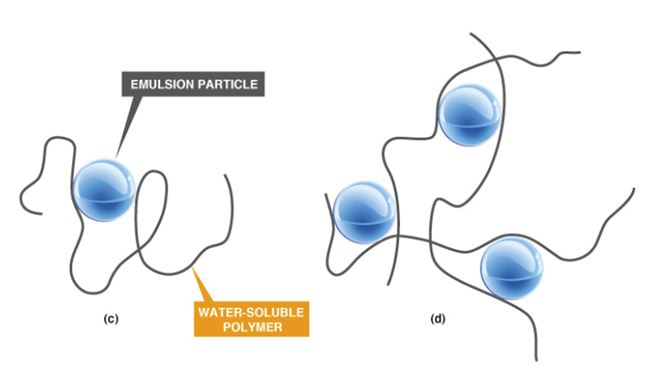

In (c), high-molecular weight rheology modifier associate and adsorb to the particle’s surface at multiple points. When these high-molecular agents encounter another particle, they will associate and adsorb to its surface forming a bridge between the particles. As this process continues, an overall net-like structure is formed as seen in (d), raising the viscosity.

Hydrophobically Modified Alkali Swellable Emulsions (HASE)

Like alkali swellable emulsions, HASE thickeners are acid functional acrylic polymers and are activated at pH higher than pH 7 through repulsion of carboxylate anions along the polymer backbone. However, HASE polymers present enhanced viscosity because the hydrophobic groups aggregate together in the water phase in a manner similar to the way in which surfactants form micelles. These hydrophobic modifications can associate either with each other on an intra- or intermolecular basis or in combination with other hydrophobic materials, especially latexes and surfactants in a coating formulation. This is why they are often referred to as ‘associative’ thickeners.

.

.

Compared to hydrophobically modified polyurethane thickeners (HEUR), HASE thickeners have a higher molecular weight, are ionic, and have a lower hydrophobe density (i.e., hydrophobe number per molecular volume). Because of this, HASE thickeners are somewhat of a hybrid thickener, deriving some of their efficiency from hydrophobic interactions and some from molecular volume effects traditionally utilized by non-associative thickeners (e.g., ASE).

HASE rheology modifiers are less ‘shear-thinning’ or conversely more ‘Newtonian’ than ASE rheology modifiers.

.

Hydrophobically Modified Ethoxylated Urethane Resin (HEUR)

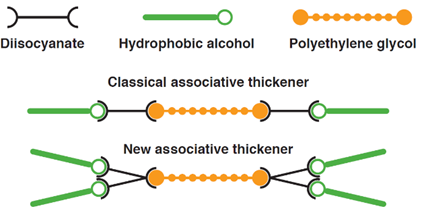

Polyurethane thickeners or HEUR thickeners compromise of a PEG backbone with hydrophobic groups at either end. By adjusting the hydrophobic groups (length, degree of branching etc.) the type of rheology can be adjusted.

HEUR thickeners offer very good flow and levelling and are more tolerant to pH changes than acrylic thickeners. The hydrophobic characteristics of polyurethane thickeners will also impart a degree of water resistance thus leading to improved weather resistance and wet scrub resistance. However, polyurethanes are sensitive to cosolvents and surfactants and can be more difficult to formulate with.

.

Organo Titanates

Organo-titanates are used to provide thixotropic structure to colloid-stabilised emulsions. Compromising of a central titanium atom and alkanolamine chelates, organo-titanates will hydrogen bond to the binder particles to produce a shear reversible gel structure. Since some structure is maintained at medium shear, high loading of brushes or rollers are possible therefore leading to thicker wet film thicknesses.

Organo-titanates are recommended to be used in combination with other thickener types such as an associative thickener or cellulosic where they give good levelling and sag resistance with low splatter.

.

References

- The impact of rheological modifiers on water-borne coatings. Colloids Surfaces: A Physicochem Eng Asp. Kastner U et al. 2001.

- Products by Function. Rheology Modifiers. San Nopco

- An Introduction to Rheological Additives For Coatings. Lawrence Industries.

- Associative thickeners for waterborne paints: Structure, characterization, rheology, and modeling. Progress in Polymer Science. Ronald Larson et al. March 2022.

- Practical Guide to Rheology Modifiers. Formulation Additives BASF.