Migratory chemicals are those chemical compounds which tend to migrate from the bulk phase of a material to its surface over time and under exposure to specific stimulus conditions. The concept of migratory chemicals has been an active topic of discussion for the materials which are under direct food contact i.e., mainly food packaging materials. In this article we will cover not only the packaging industry, but also the effect of migratory chemicals in textiles, leather, and rubber industry.

..

Mechanism of Chemical Migration

Compounds which have lower molecular weight and lower solubility in the material are the most prone chemicals to migrate to the surface. Migration of chemical substances is a diffusion process subject to both kinetic and thermodynamic control. The kinetic dimension of migration dictates how fast the process of migration occurs. The thermodynamic dimension dictates how extensively the chemical will migrate. For example, migration may proceed at a slow rate (kinetically unfavorable) but, if the chemical migrant has a higher affinity for the outer environment, then given enough time, it will still migrate extensively (thermodynamically favorable).

All migrations require:

- A donor environment (which contains the migratory chemical)

- A receptive environment (for which the migratory chemical has affinity)

- A carrier (which carries the migratory chemical from the donor to receiver)

- Stimulus conditions (which accelerate the migration process)

We will explore the different donor and recipient environments based on the different application areas, but all application areas have common/similar carrier systems.

Most common carrier systems are residual solvents, monomers, and water (humidity)

.

Migration in Food Packaging Materials

Food production is industrialized in many parts of the world and the global food supply chains are logistically demanding. With the increasing consumption of snack and take-away foods and moves to smaller pack sizes to satisfy smaller households and convenience eating, it seems inevitable that the use of packaging materials in contact with our diet will continue to increase. Hence there is even more need to understand the issue of migratory chemicals, as some of these chemicals are toxic, detrimental effects on health can arise.

Food and beverages can be very aggressive products and may interact strongly with materials that they touch. Collectively, they are as good as many of the solvents used in a chemistry laboratory. For example, food acids can corrode metals, fats and oils can swell and leach plastics, and beverages can disintegrate unprotected paper and carton board. In fact, no food contact material is completely inert and so it is possible for their chemical constituents to ‘migrate’ into the packaged food.

.

Factors controlling chemical migration:

- Composition of packaging material

- Nature of food material

- Extent of contact (direct or indirect)

- Temperature of contact

- Duration of contact

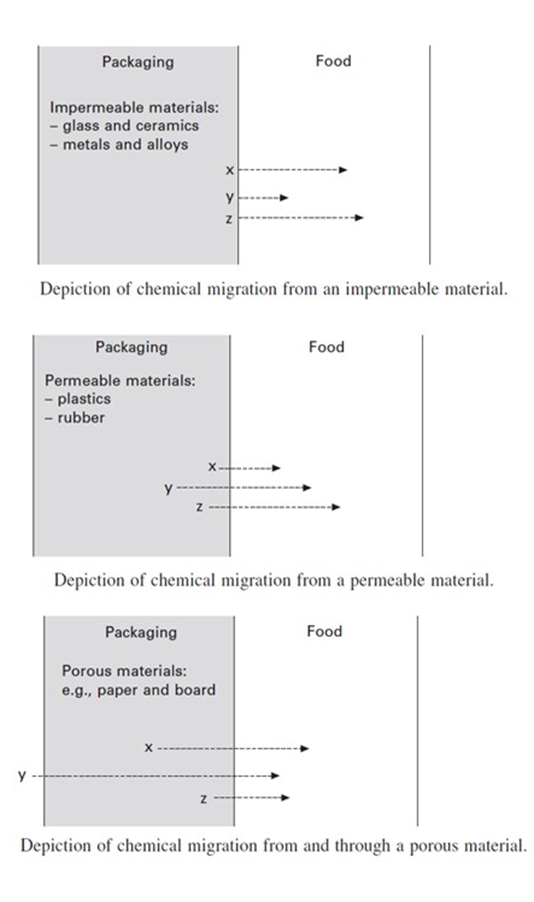

Migration in food packaging materials can be understood using three general cases as showed in the figure.

Impermeable materials like glass and metals are absolute barrier and do not permit migration from the interiors. Migration is confined to the surface phenomenon only.

In case of permeable materials like plastics and rubber, the material offers some limited resistance to migration but this can occur not only from the surface but also from the interior of the material too.

For porous materials like paper, one can expect quick migration of chemicals with little hindrance offered.

..

Which Chemicals tend to Migrate?

As we had discussed earlier, chemicals with low molecular weight, small molecular size, and limited solubilities tend to migrate out. Amongst the wide variety of chemicals which are used for manufacturing food packaging products, the following classes of chemicals are known to migrate to the surface:

.

- Plasticizers

Diethylhexyl phthalate (DEHP), Dibutyl phthalate (DBP), Diisobutyl phthalate (DiBP)

.

- Surfactants

Slip additives and fatty acid amides (primarily erucamide and oleamide)

.

- Waxes

Paraffin wax, polyethylene wax, carnauba wax

.

- Antioxidants

Butylated hydroxytoluene (BHT), Butylated hydroxyanisole (BHA), Irganox 1010

.

- UV stabilizers and photoinitiators

Tinuvin 622, Chimasorb 944, Tinuvin 326, Benzophenone

.

- Heat stabilizers

Metal salt blends, organotin compounds, lead compounds

.

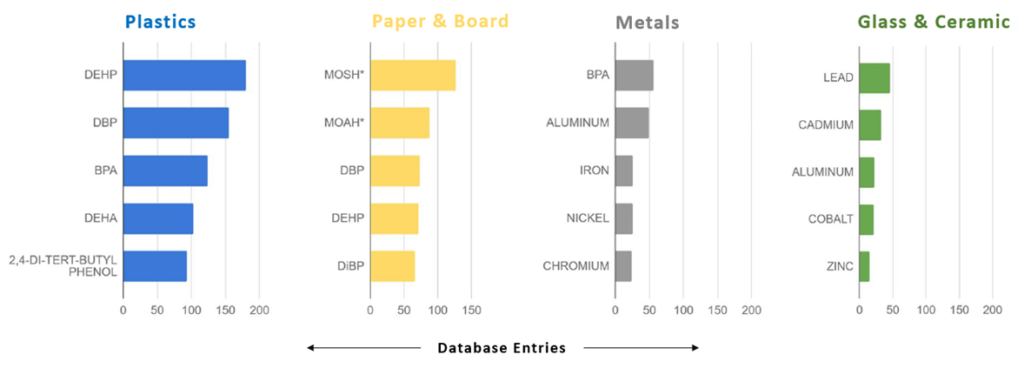

Birgit Gueke and her research team had published a research in 2022, where they thoroughly studied and researched the migratory chemicals through different materials of food packaging. The image below summarizes their findings.

.

*Note: Mineral oil saturated hydrocarbons (MOSH) and Mineral oil aromatic hydrocarbons (MOAH). MOSH and MOAH are complex mixtures of hydrocarbons that cannot be resolved into individual substances and do not have a unique CAS num.

..

Migration in Textile Products

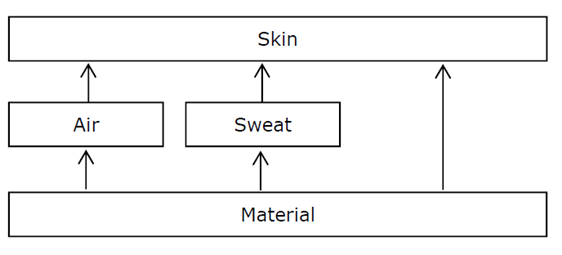

Two processes typically determine migration of substances from products to the skin. Firstly, the substance is transported in the product to the product surface. Secondly, from the surface the substance may be transferred to skin.

.

Direct exposure via the skin takes place when consumers use textiles. High body temperature and body moisture are factors that may increase the transport of the substances from the textile to the skin. Direct exposure can also take place when children suck on textiles.

.

One of the main processes in textile production is the coloring step in which the dyes are added, and these dyes are the most probable components in textiles which tend to migrate to the surface.

Some dyes, e.g., direct and acid dyes, bind very loosely to the fibers and therefore easily migrate to the skin. Disperse dyes are strongly bound to fibers, although low quality dyeing can decrease this binding and increase human exposure. Substances that are highly water-soluble are removed during the washing process. This means that most surfactants, emulsifiers, and other water-soluble substances are normally washed out before consumer use, if effective washing is performed. Substances such as pigments, plasticizers and flame-retardants are strongly bound to textile fibers.

Benzothiazole is a commonly used chemical in manufacturing of dyes and is known to cause depression of central nervous systems, kidney & liver toxicity, and skin allergy.

.

Migration in Leather Products

Have you ever noticed that white shoes gain a pinkish hue before they have been worn? Or a leather briefcase becomes sticky during storage? These phenomena are due to the migration of chemicals in leather products.

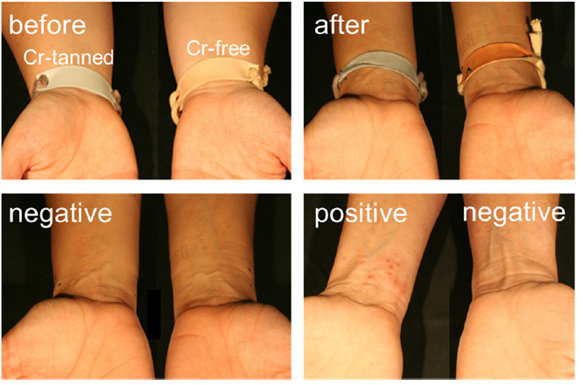

However, the most common migration problem observed in leather goods is in chromium-tanned leather.

Chromium tanning is widely followed because of its multiple advantages. It is practiced using a using a basic trivalent chromium sulfate salt, Cr(OH)SO4. It is this trivalent chromium which binds to the proteins, primarily collagen, of the skin forming a complex.

The release of trivalent and hexavalent chromium from leather, even for the same leather, is strongly affected by pre-exposure conditions and exposure conditions.

The release of total (trivalent and hexavalent) chromium is highest for new leather since excess chromium is released.

.

The risk for release of hexavalent chromium from leathers increases for:

- Chromium-tanned leathers without any antioxidants, vegetable tannins, or reducing acids.

- Tanning or manufacturing at too high pH

- Exposure to dry air (< 35% relative humidity) or UV light prior to skin contact.

.

Migration in Rubber Products

Unlike all the previous topics, migration of chemicals in rubber is to be taken in a positive sense. Formulators plan for migration of a few chemicals through the rubber phase for better performance properties. For example, waxes and p-phenylenediamines antiozonants (protect rubber from oxygen and ozone) rely heavily on the migration mechanism to provide optimum protection of rubber products during service against degradation by ozone.

.

Ways to prevent “unintentional” migration of chemicals

- Using higher molecular weight compounds.

- Adding functional groups in the material matrix to interact with the migrating chemical and prevent its migration.

- Have an inert coating as a top layer to restrict interaction of migratory chemicals with the outer environment.

..

.

References

- Chemicals from textiles to skin: an in vitro permeation study of benzothiazole. Iadaresta et al. Environmental Science and Pollution Research. 2018.

- Chemical migration into food: an overview. Castle et al. Chemical Migration and Food Contact Materials. 2007.

- Chromium and leather: a review on the chemistry of relevance for allergic contact dermatitis to chromium. Hedberg. Journal of Leather Science and Engineering. 2020.

- Hazardous substances in textile products. M. Nijkamp et al. National Institute for Public Health and Environment. 2014.

- Systematic evidence on migrating and extractable food contact chemicals: Most chemicals detected in food contact materials are not listed for use. Geueke et al. Critical Reviews in Food Science and Nutrition. 2022.

- Migration. Muncke. Food Packaging and Health. 2013.

- Migration and bleeding in footwear and leather goods production – Leather International. 2008.

- Physical and chemical modifications of poly(vinyl chloride) materials to prevent plasticizer migration – Still on the run. Ma et al. Reactive and Functional Polymers. 2019.

- Hazardous Chemicals in Food Packaging – A threat to human health.

- Textile Dermatitis: Are you Allergic to Your Clothes. The Eczema Company. 2019.